Projects

Collection of the projects I have worked on and lessons learned.

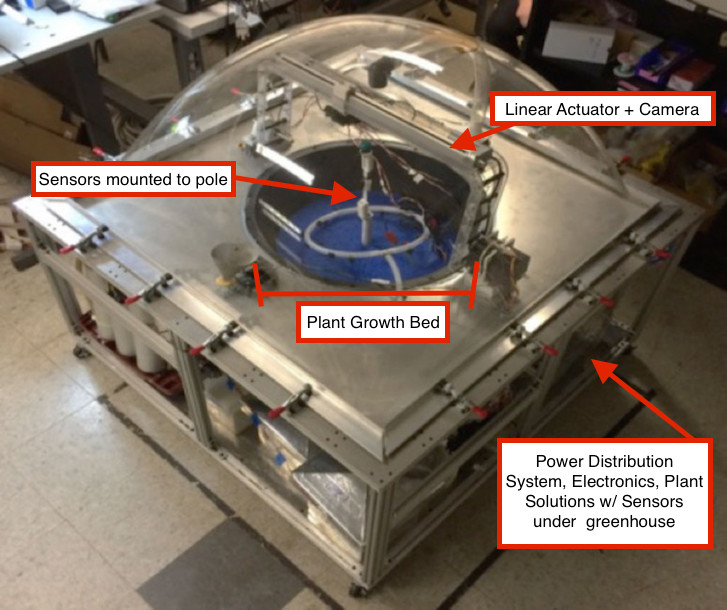

Martian Greenhouse Prototype: Lead Electrical & Software Engineer and Atmosphere Control Engineer

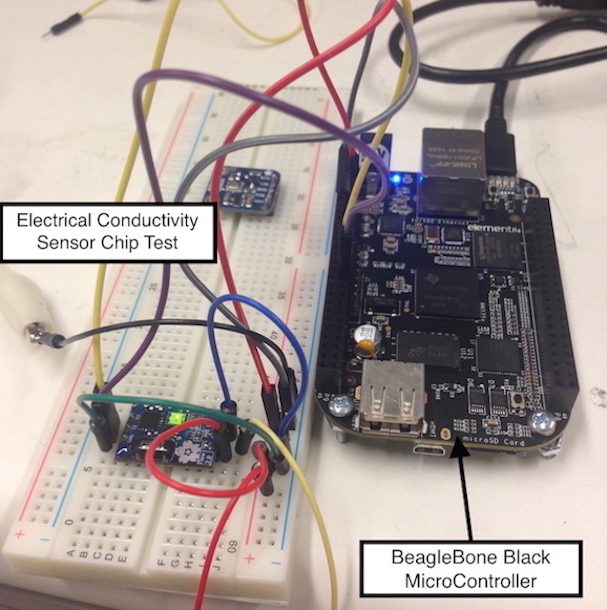

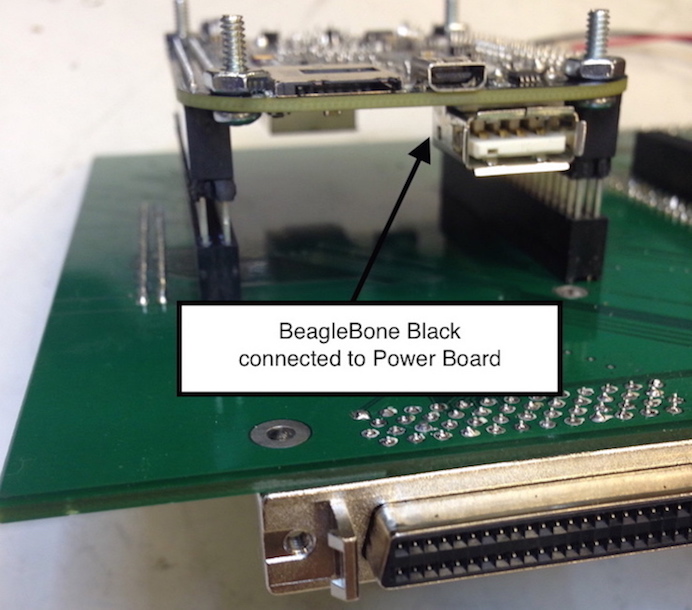

Responsibilities: Worked with a team of 12 students to develop a reduced-scale prototype for a pre-deployable Martian greenhouse that will enable research-grade, plant sciences studies in closed environments. I led the subsystem in charge of designing/manufacturing the electrical hardware and developing the software for the project. We used two BeagleBone Black microcontrollers, a 35-sensor suite, and control algorithms to monitor plant health and deliver the necessary conditions for maintaining the closed environment. I directly worked on determining atmospheric design requirements, contributing to driver code for all subsystems' sensors, developing the control logic of the system and wiring the support circuitry for the sensors.

Language: Python

Interfaces: UART, ADC, I2C

Design: Eagle, Altium

Sensor Suite: Beagle Bone Black Microcontrollers, EZO™ pH Circuit, Dissolved Oxygen, Temp, Liquid Level, Flow Meter, pH, Soil Moisture, Total Pressure, Light (PAR), Relative Humidity, Oxygen, CO2

Lessons Learned: This project taught me a significant lesson in allocating cushion time into deadlines for unexpected parts delays, trying to understand poorly writted specification sheets, and scheduling availability of team members' with specialized skills.At the end of the year, my subteam and I had writted the calibration and driver code for every sensor type and successfully tested all of the 35 sensors. We also had a preliminary iteration of our control algorithms to control the sensors together and the wiring and power distribution systems in place. However, we had to keep pushing deadlines because we did not realize the time delays that poor specification documents and malfunctioning parts would cause. Looking back I would have worked with my team to descope the amount of sensors and combine any functionality that we could to reduce the variety of hardware we had to learn to integrate.

Strobe Water Lab with Range Finder Theremin Control Interface

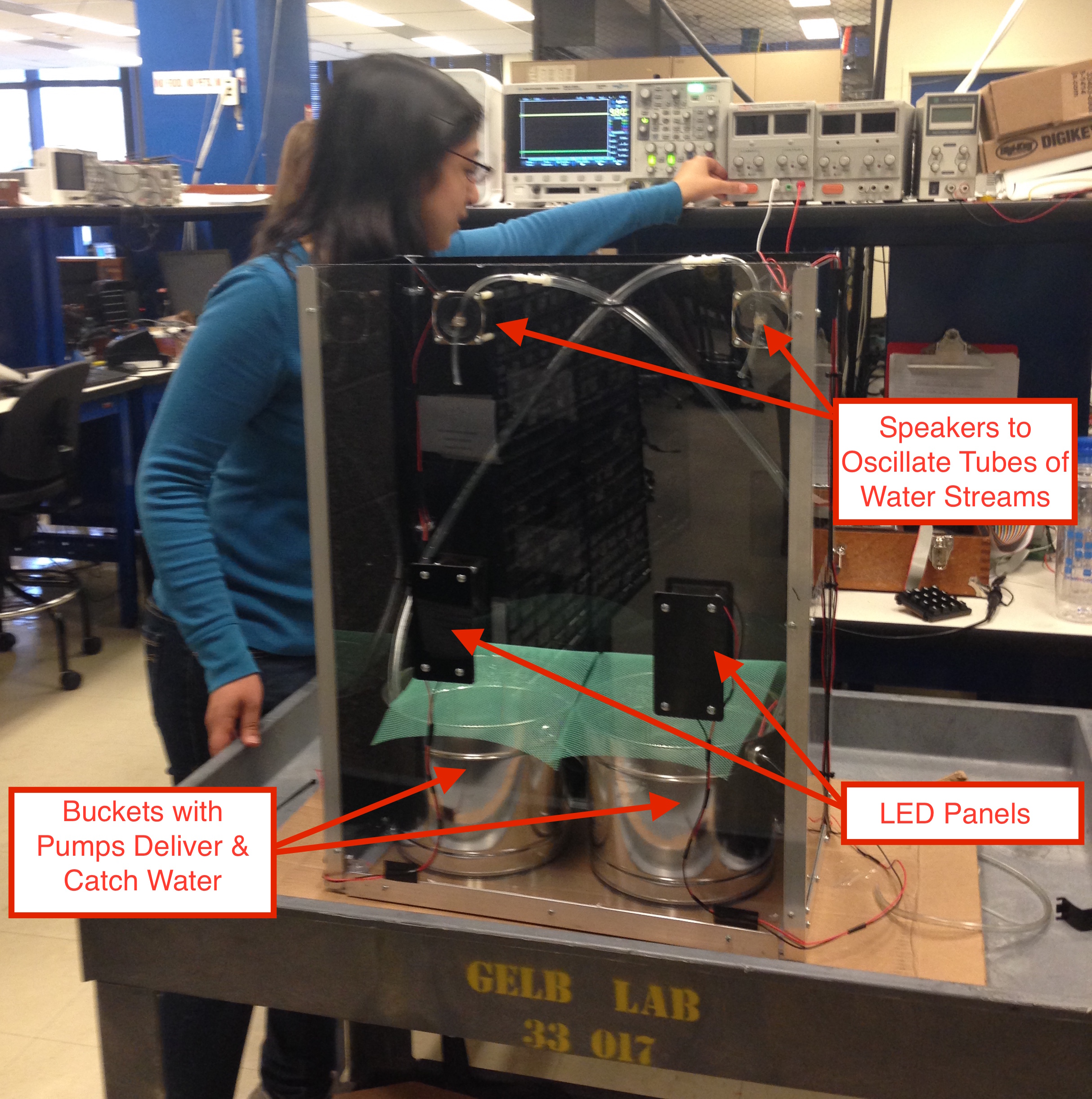

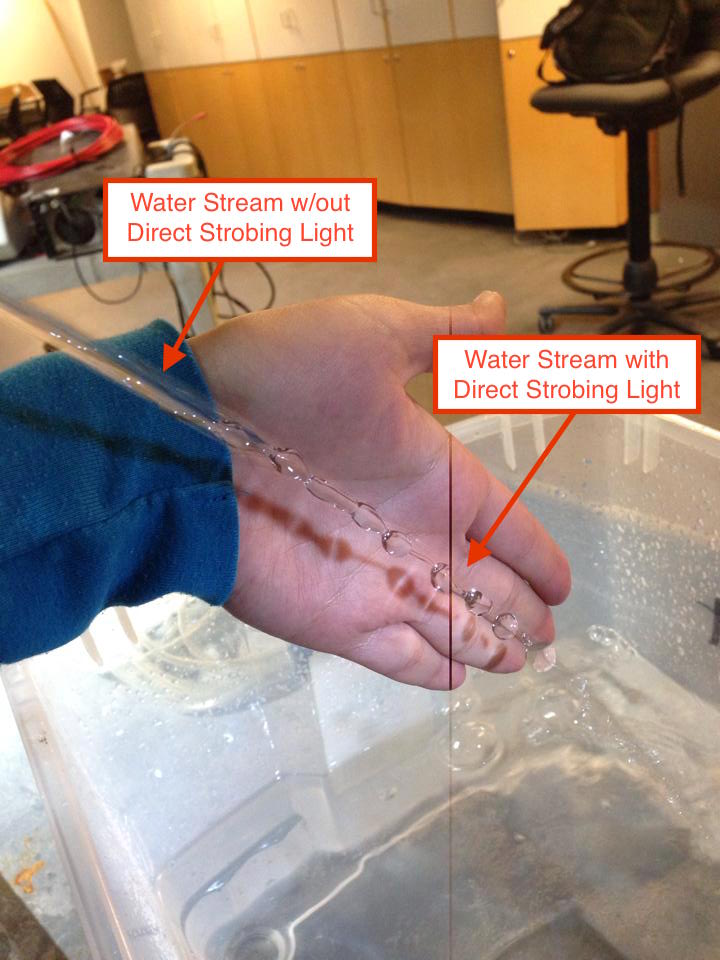

What happens when you put together strobe lights and oscillating water? During my senior year of MIT, I designed and built a strobe water lab with an instrument-based control paradigm. I wanted to add an interesting control paradigm using an instrument to the typical Strobing Water Museum Display.

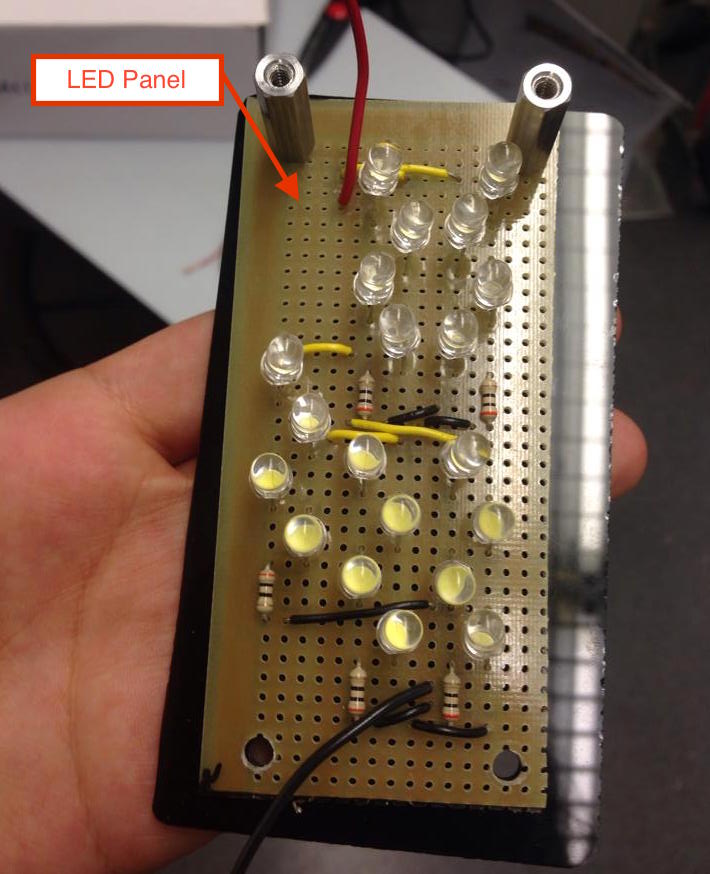

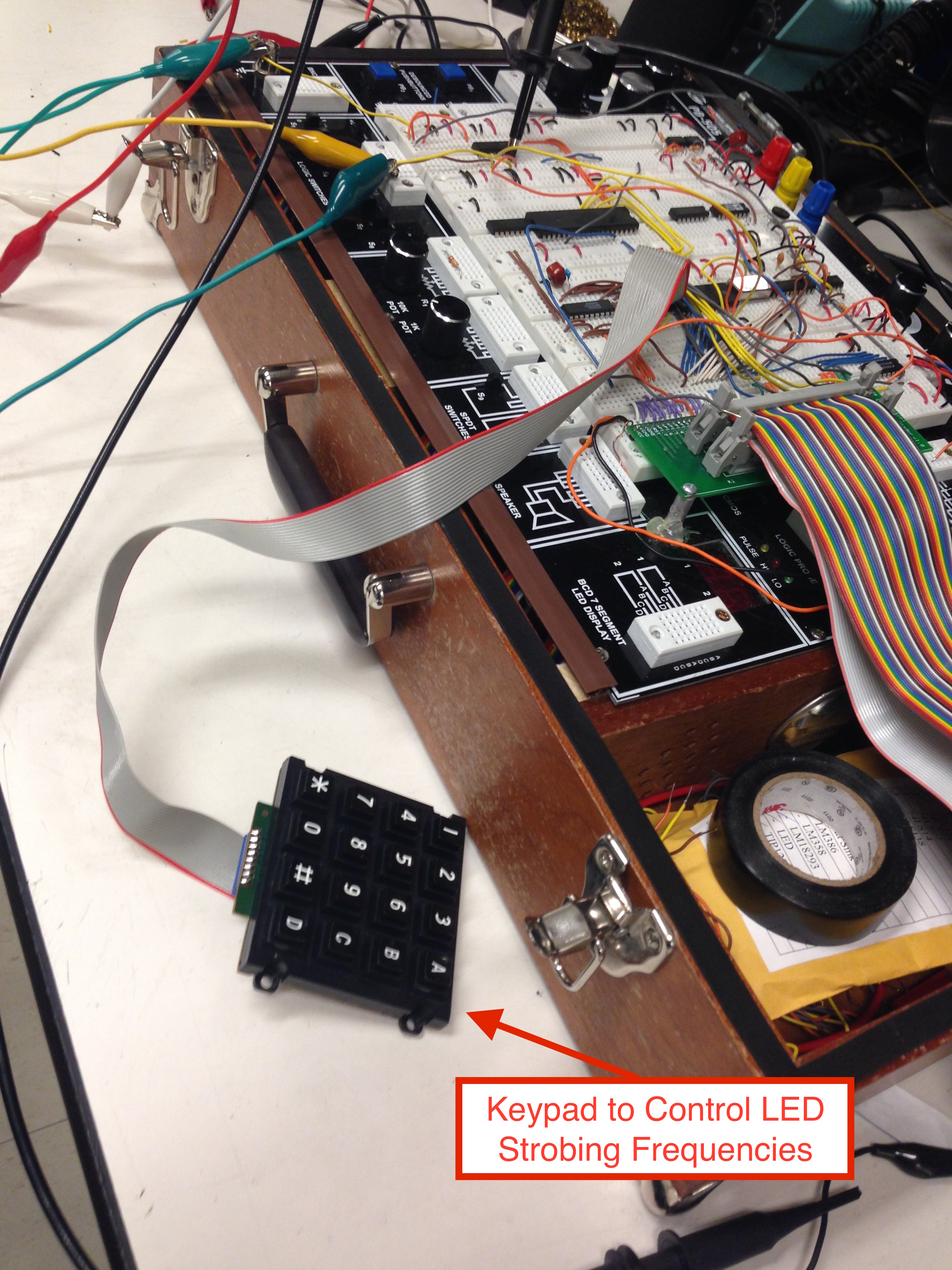

Structure: I constructed a waterproof, acrylic box in the AeroAstro machine shop and MIT Cypress Engineering Design Studio. I soldered together LEDS and wrote 8051 assembly code to strobe them at a fixed freq of 80Hz. The LED panels were fixed to the box such that they were directed at streams of water that were being pulsed by two speakers.

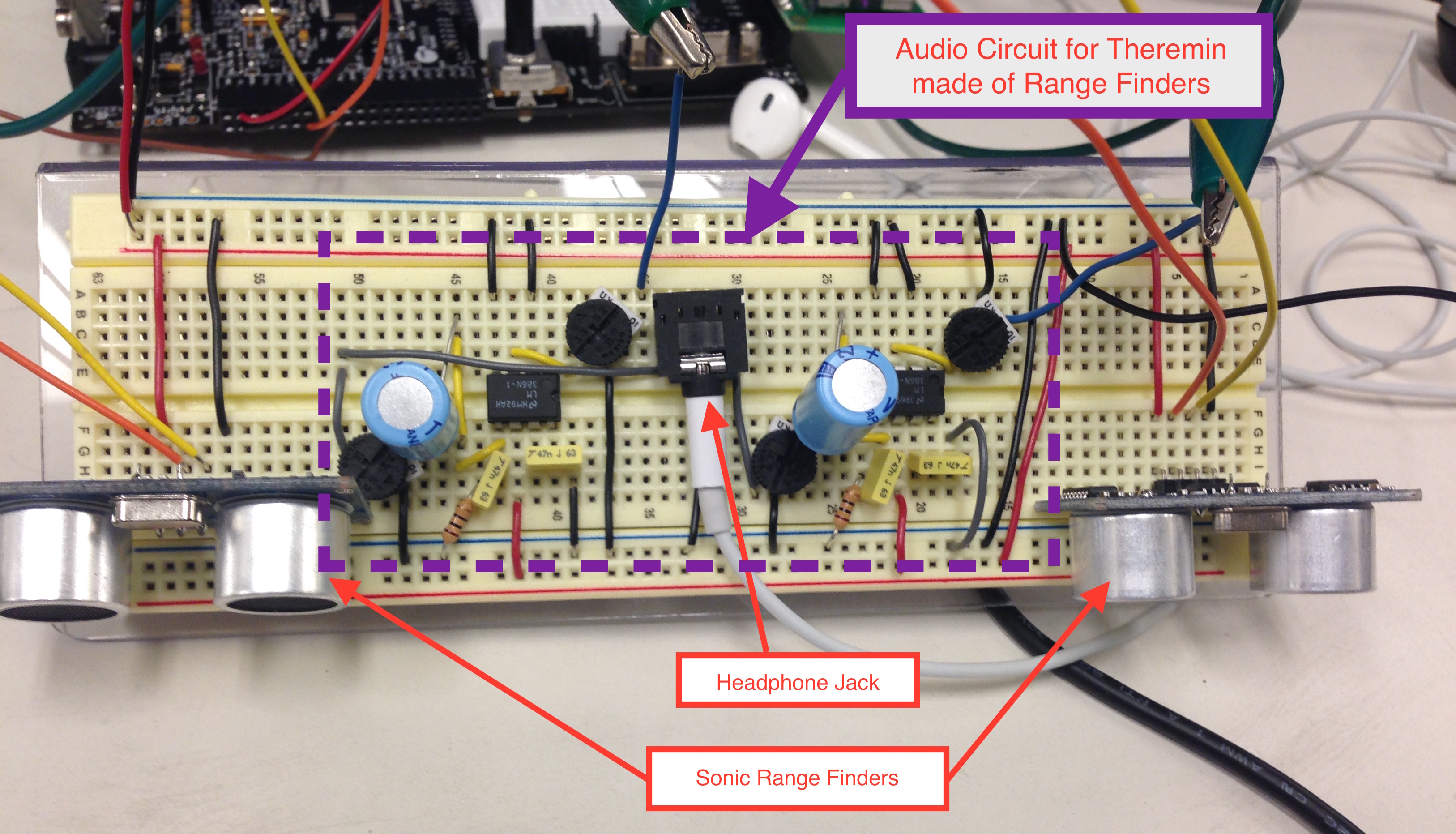

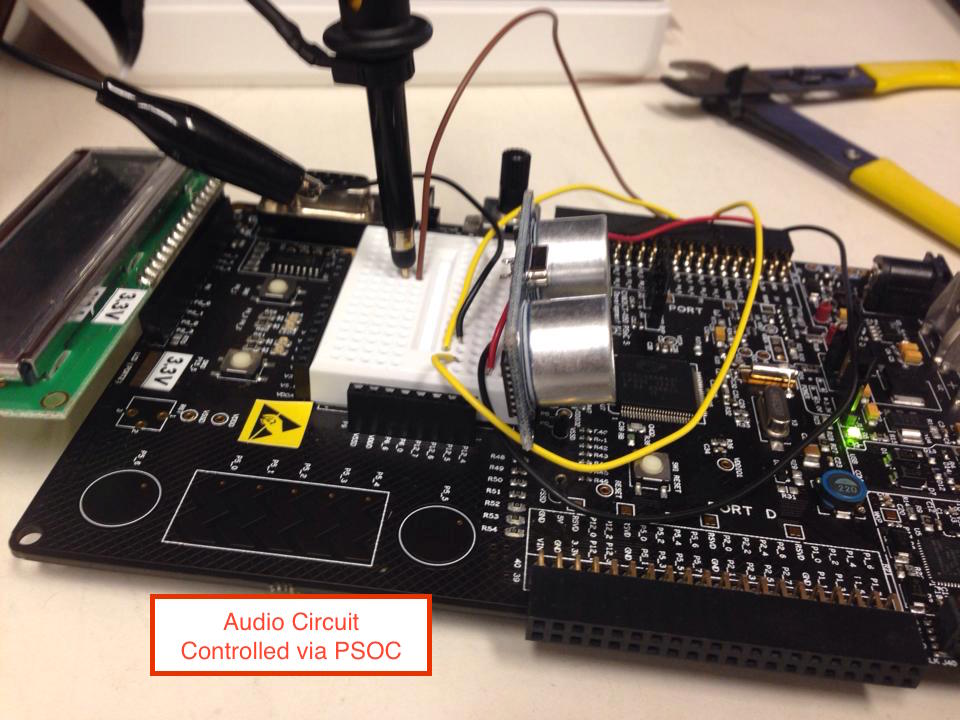

Control Interface: As I was thinking about the control paradigm for my lab, a friend had showed me a youtube video of a Theremin. Traditionally, a theremin is an instrument made of two metal antennas. When someone moves there hands around the antennas, the proximities of one of the user's hands controls frequency oscillations and the other controls volume of the instrument. For my project, I connected two range finder sensors to an audio circuit. The theremin would output lovely notes as the user controlled the frequency of the speakers by moving their hands up and down above the range finders. Changing the frequency of the speakers would create the illusion that the stream of water is a stationary, falling or rising chain of droplets.

Language: C, 8051 Assembly

Design: Eagle

Hardware: Sonic Range Finders, 8255 Programmable Peripheral Interface Chip, LM18293, Schmitt Inverter, Multiplexer, 74C922 ( for the keypad), PSoC (Programmable System on Chip), hobby water pumps, desktop speakers

Lessons Learned: From this project, I learned the value of building and testing early. I created this working display in the span of six weeks, however the project would not have been successful if I had not realized early that I needed to test fast. I had to re-order some new LEDs when I wasn't satisfied with my first test iteration. I learned that lab resources also had wait times and as always in engineering, if a component doesn't work, then you need time to redesign and test.

Artificial Gravity Test Vehicle

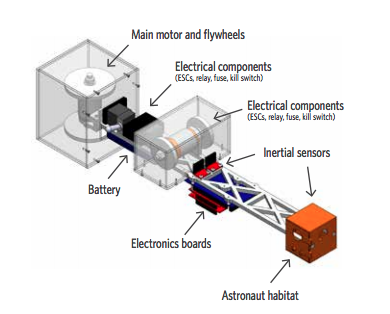

Description: During my junior year at MIT, my three teammates and I practiced our knowledge of dynamics by designing a proof of concept artificial gravity test vehicle composed of an aluminum truss with perpendicular flywheels and a habitat. The objective of the vehicle was to demonstrate the practicality of using flywheels to control steering and inducing artificial gravity on a habitat with astronauts. The goal for this test vehicle was to create an environment in which astronauts do not experience the physiological deconditioning typical of a weightless environment and therefore the need for individualized countermeasure designs would be eliminated.

Structure: Our artificial gravity test vehicle is made of a two-foot long aluminum truss that has a scaled-down habitat for a Lego astronaut at one end and a set of flywheels at the other end. Due to the principles of conservation of angular momemtum, the spinning of the flywheel at the end of the truss causes the entire vehicle to rotate in the direction opposing the spinning. This proof-of-conecpt was aimed at determining the g's that could be induced on the habitat without the use of fuel.

Our experiment created 0.1-0.4g's of acceleration on the mini-habitat. A second set of flywheels near the center of the truss were used to investigate effects of slew and tilt on the vehicle's gravity vector.

Outreach: This project served as a great outreach opportunity to get middle and high school students excited about STEM fields. As the point person for outreach, I organized two classes about microgravity and our project for students across New England during MIT's Spark and Splash weekends

Lessons Learned: From being involved in every phase of this project: design, prototype, build, test and data acquisition, I learned about the importance of testing early, scheduling deadlines, and best practices in interfacing with mentors at NASA JSC and MIT.